-

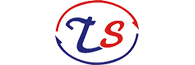

We Provide Stamping Parts Production Services

Tiansheng Company produces all kinds of stamping inner plates, outer plates, and stamping sub-parts. If you have the need to outsource the production of stamping parts, please contact us immediately.

Send Email Details

Our production equipment: mechanical press line, hydraulic press line

Main experimental facilities: three-coordinate/blue light/gauge. -

We Provide Welding Production Services

Tiansheng produces all kinds of assembly parts (including four doors and two covers, fenders, side panels, etc.), with advanced and complete welding technology, and the assembly parts are directly supplied to OEMs such as BMW Brilliance, Volvo, and SAIC-GM. If you have outsourced assembly parts needs, please contact us.

Send Email Details -

We Provide PVC Coating Services

Tiansheng undertakes the PVC coating business for auto parts. Tiansheng is a professional and well-known auto parts manufacturer in China. Its products are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC GM. If you are looking for an auto parts supplier, please contact us.

Send Email Details -

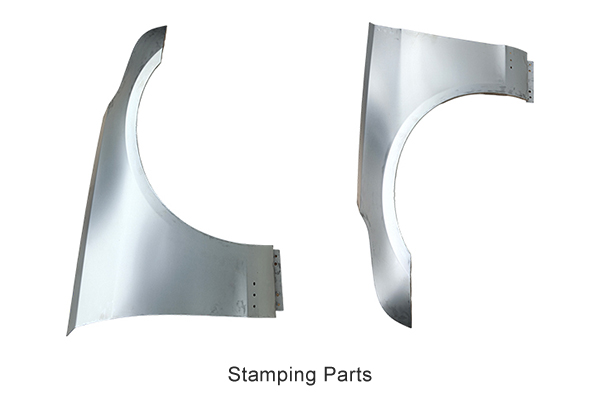

We Provide Electrophoresis Services Phosphating Process

Tiansheng is a professional and well-known auto parts manufacturer in China. Tiansheng's auto parts are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC GM. If you need to outsource electrophoresis business, please contact us.

Send Email Details -

We Provide Parts Packaging Services

We provide parts packaging services

Send Email Details

Tiansheng is a well-known auto parts supplier in China. Parts are packed in paper or wooden boxes. The wooden boxes are sterilized at high temperatures and are free of insects and eggs. They can be shipped to North America and Europe. If you are looking for an auto parts supplier, please contact Tiansheng (email: caoyuyan@autolpj.com). -

We Provide Parts Packaging Services

We provide parts packaging services

Send Email Details

Tiansheng is a well-known auto parts supplier in China. Many overseas service parts of Volvo and other OEMs use Tiansheng's cartons. If you are looking for an auto parts supplier, please contact Tiansheng (email: caoyuyan@autolpj.com).