Electrophoresis Line 3 Silane Processing Silane Process, Larger Size

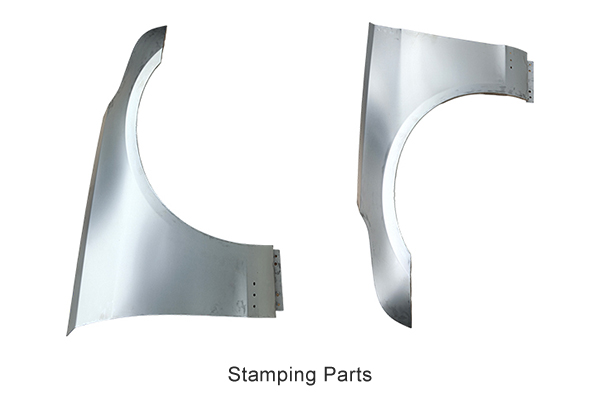

Tiansheng is a professional and well-known auto parts manufacturer in China. Tiansheng's auto parts are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC GM. If you need to outsource electrophoresis business, please contact us.-

Tiansheng is a professional and well-known auto parts manufacturer in China. Tiansheng's auto parts are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC General Motors. If you are looking for an auto parts supplier, please contact Tiansheng (email: caoyuyan@autolpj.com).

Investment background of electrophoresis line 3:

In view of the fact that my country's new energy vehicles have entered a new stage of rapid development, Tiansheng has continuously increased its investment in innovation and research and development, and actively seized the new energy track. From the end of 2020 to the end of 2021, Tiansheng invested in the construction of electrophoresis line 3 to support the electrophoresis business of new energy vehicle accessories (such as battery boxes).

Advantages of silane line:

More environmentally friendly process (silane material is used for pre-treatment, phosphorus-free and more environmentally friendly)

A wider range of materials (applicable to cold-rolled plates, electrogalvanized plates, hot-dip galvanized plates, aluminum plates, zinc-nickel alloy plates, steel tack, etc.)

Larger workpiece passing size (L3800×W1000×H1700)

More abundant production capacity (annual design capacity reaches 2 million pieces)

Larger single-point load-bearing capacity (500 kg)

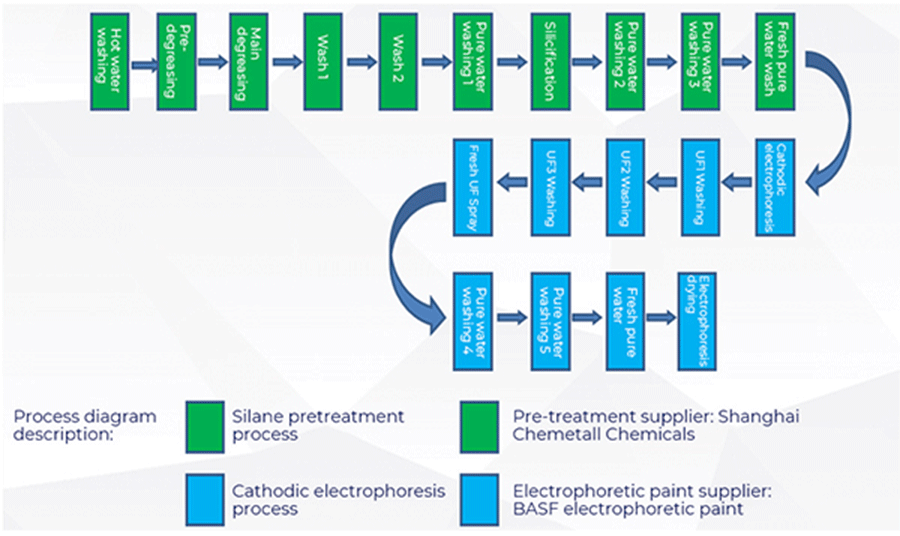

Silane process flow:

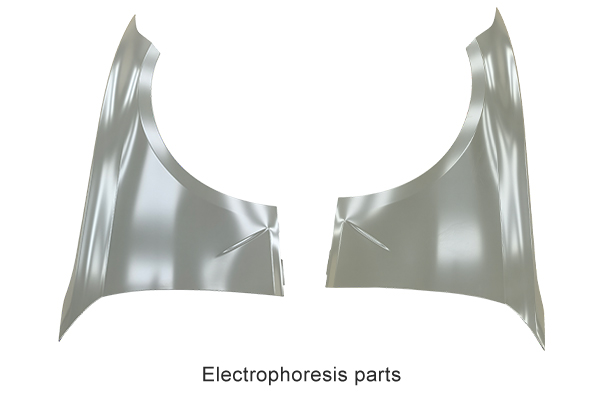

Tiansheng Company's quality control in the electrophoresis link (all records are kept):

1. Equipment status inspection before the start of the class.

2. Confirmation of the status of the electrophoresis hanger before the start of the class.

3. Monitoring of electrophoresis pre-treatment process parameters.

4. Monitoring of electrophoresis process parameters.

5. Furnace temperature curve (once a month).

6. 100% full inspection of electrophoresis parts hanging down (visual, hand touch)

7. Paint film measurement.

8. Physical and chemical analysis experiments (grid test, corrosion resistance test, etc.).

Note: Physical and chemical analysis experiments are carried out according to customer requirements.

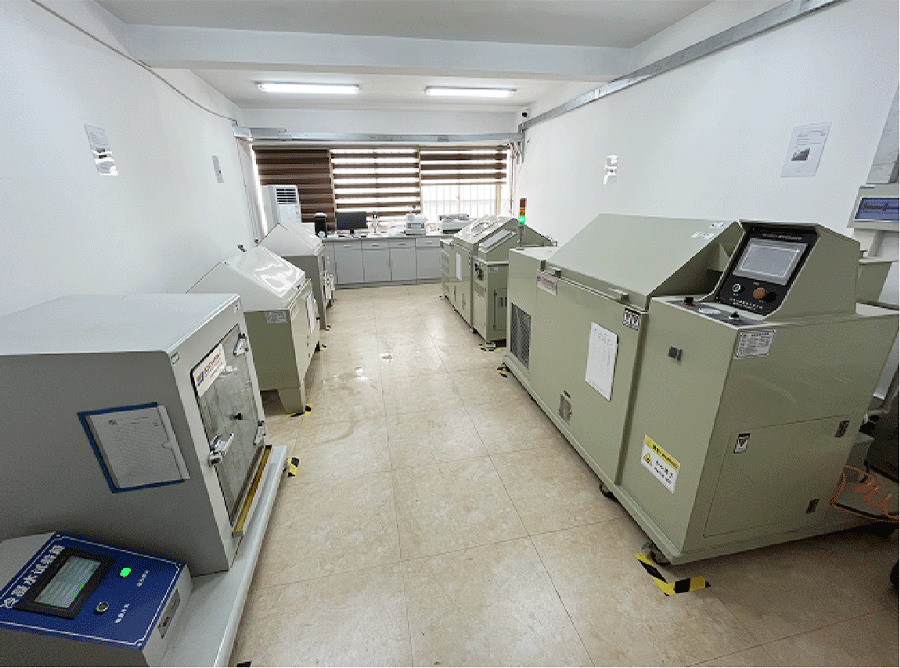

Test items that can be carried out in the electrophoresis workshop:

CASS test, condensation water test, cyclic corrosion test, salt spray test, air tightness test, etc.