Electrophoresis Line 2 Silane Processing Silane Process

Tiansheng is a professional and well-known auto parts manufacturer in China. Tiansheng's auto parts are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC GM. If you need to outsource electrophoresis business, please contact us.-

Tiansheng Company is a professional and well-known auto parts manufacturer in China. Tiansheng's auto parts are directly supplied to OEMs such as BMW Brilliance, Volvo, SAIC Volkswagen, and SAIC General Motors. If you are looking for an auto parts supplier, please contact Tiansheng Company (email: caoyuyan@autolpj.com).

Basic information of electrophoresis line No. 2:

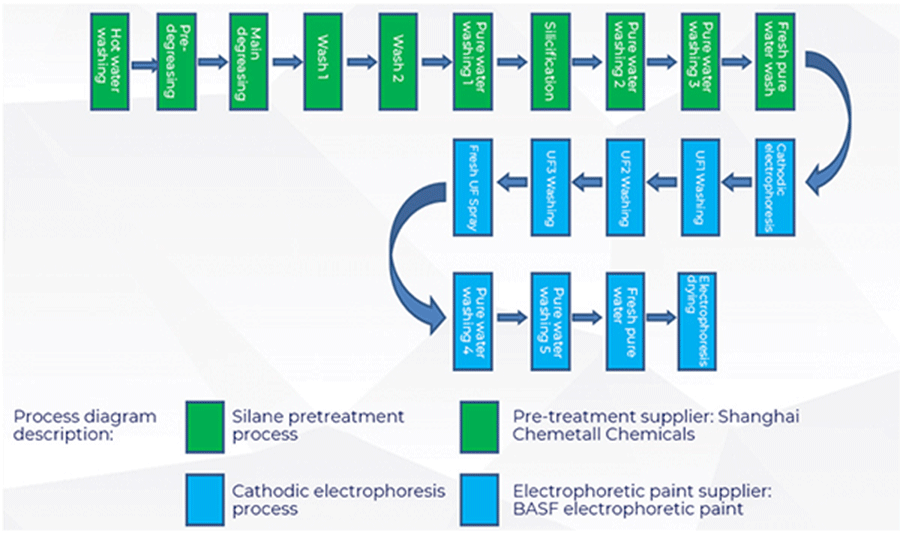

In October 2019, the company invested in the construction of electrophoresis line No. 2, with an annual design capacity of 2 million pieces. Energy-saving and environmentally friendly silane materials are used in the pretreatment, and PPG paint is used in the electrophoresis process. The environmental protection and safety assessment procedures of the electrophoresis line are complete and have passed the acceptance.

The electrophoresis line uses a forged suspension chain with a single-point load-bearing capacity of 500 kg.

Introduction to the advantages of silane line:

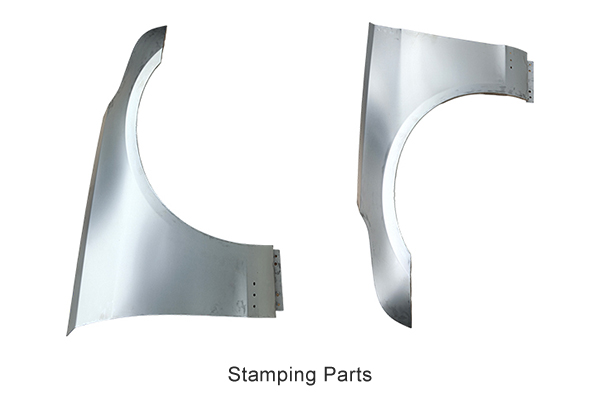

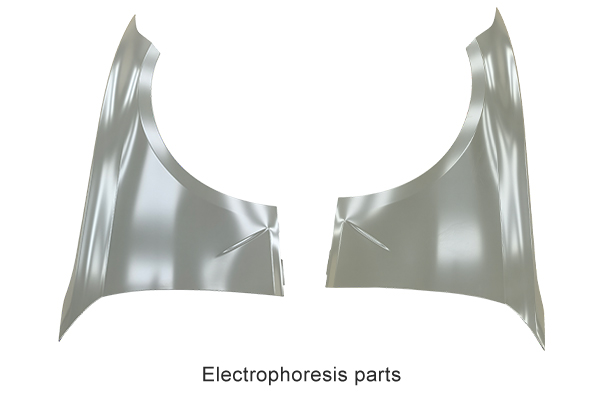

Maximum pass size (unit: mm): L3800×W800×H1600. It can carry out electrophoresis production of all white body sub-assembly parts except white body assembly and chassis assembly. Such as side panels, four doors and two covers, front and rear fenders, front and rear panel assemblies, etc.

Applicable materials for coating workpieces: cold-rolled plates, electrogalvanized plates, hot-dip galvanized plates, aluminum plates, zinc-nickel alloy plates, steel sheets, etc.

The latest RTO treatment equipment is used for waste gas treatment to ensure that waste gas emissions meet the standards. Wastewater treatment also meets the prescribed emission standards.

Silane process flow:

Tiansheng Company's quality control in the electrophoresis link (all records are kept):

1. Equipment status inspection before the start of the class.

2. Confirmation of the status of the electrophoresis hanger before the start of the class.

3. Monitoring of process parameters before electrophoresis treatment.

4. Monitoring of electrophoresis process parameters.

5. Furnace temperature curve (once a month).

6. 100% full inspection of electrophoresis parts (visual, hand touch)

7. Paint film measurement.

8. Physical and chemical analysis experiments (grid test, corrosion resistance test, etc.).

Note: Physical and chemical analysis experiments are carried out according to customer requirements.

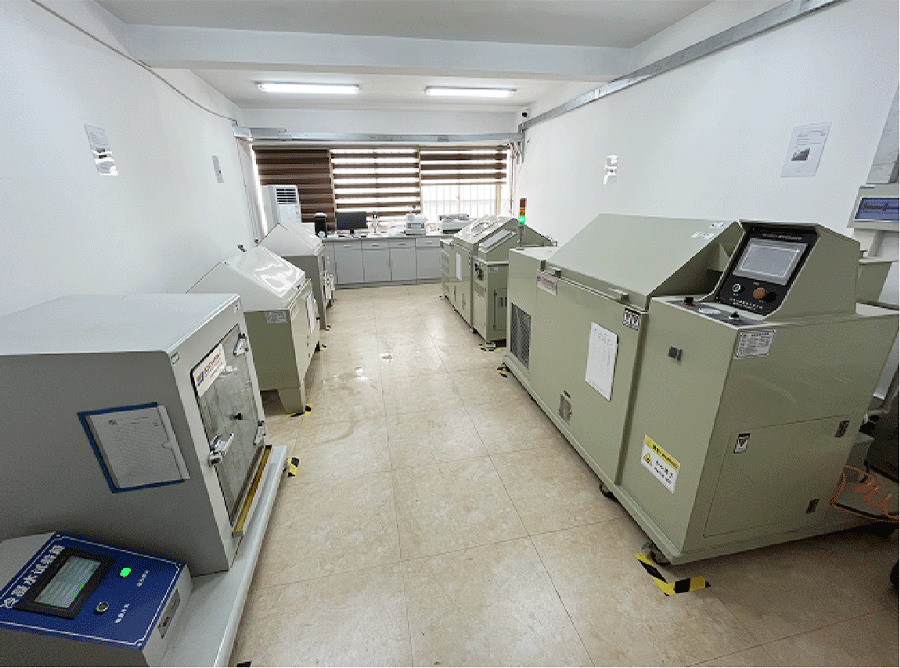

The test items that can be carried out in the electrophoresis workshop include: CASS test, condensation water test, cyclic corrosion test, salt spray test, air tightness test, etc.