What are the unique advantages of mechanical press production line in terms of stamping speed?

Release Time : 2024-12-16

In modern manufacturing, mechanical press production line has shown many unique advantages with its excellent stamping speed, and has become a key tool for many industries to improve production efficiency.

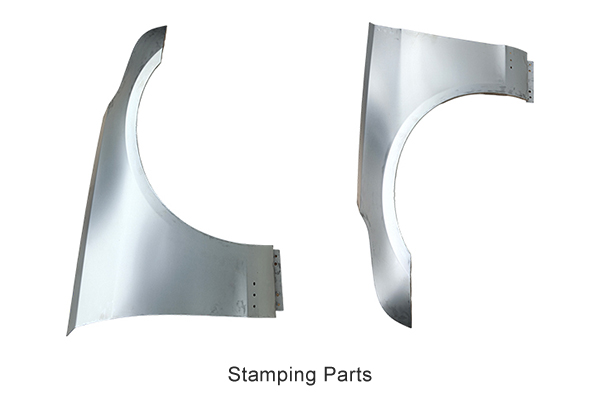

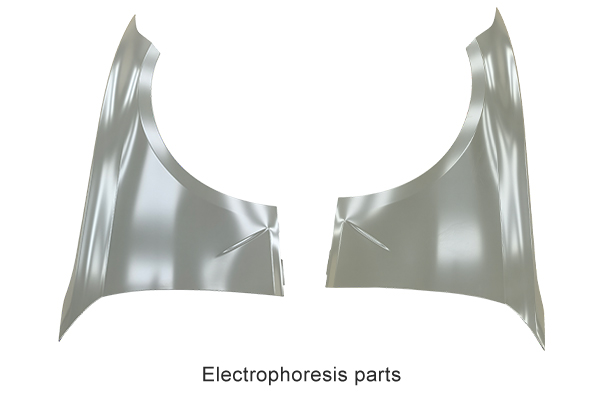

Mechanical press production line has a very high stamping frequency. Its advanced transmission mechanism and precise control system work together to make the number of stamping times per minute far exceed that of traditional single-machine stamping equipment. For example, some high-end mechanical press production lines can stamp dozens or even hundreds of times per minute. This high-speed stamping capability is of great significance in large-scale production, such as the automobile manufacturing industry, where a large number of body parts, chassis components, etc. need to be stamped. Mechanical press production line can quickly repeat stamping actions and complete the production tasks of a large number of parts in a short time, greatly shortening the production cycle of automobiles and meeting the market's demand for rapid delivery of automobiles.

The continuous stamping working mode of this production line has greatly improved the overall production efficiency. Unlike single-machine stamping equipment that needs to stop for material loading and unloading after a single stamping, mechanical press production line achieves seamless connection of the stamping process through automated feeding and unloading devices. After the raw materials are fed into the first stamping station, they pass through multiple stamping stations in sequence, and different stamping processes such as punching, blanking, bending, etc. are continuously completed at each station until the final formed product is automatically unloaded. This continuous operation mode is like an efficient production line, which minimizes the idle time in the production process and increases the production efficiency exponentially. Taking the stamping of electronic equipment shells as an example, the production line can quickly stamp metal sheets into shells of various complex shapes, and can ensure a high production cycle to ensure that electronic equipment can be supplied to the market in a timely manner.

In addition, the mechanical press production line performs well in the stability of stamping speed. The high-precision servo motor or advanced hydraulic system it adopts can accurately control the movement speed and stroke of the slide of the press. During the long continuous stamping process, no matter what material, shape and size of the stamping parts are faced, the stamping speed can be maintained at a stable level, and there will be no product quality problems caused by speed fluctuations. This is especially important for some industries that have extremely high requirements for product precision and consistency, such as aerospace parts manufacturing. Stable stamping speed ensures that each component can be formed according to precise process parameters, laying a solid foundation for the high quality and high reliability of aerospace equipment.

In summary, the mechanical press production line has demonstrated unparalleled unique advantages in stamping speed with its high stamping frequency, continuous stamping working mode and stable speed control, which has effectively promoted the efficient and rapid development of the manufacturing industry.

Mechanical press production line has a very high stamping frequency. Its advanced transmission mechanism and precise control system work together to make the number of stamping times per minute far exceed that of traditional single-machine stamping equipment. For example, some high-end mechanical press production lines can stamp dozens or even hundreds of times per minute. This high-speed stamping capability is of great significance in large-scale production, such as the automobile manufacturing industry, where a large number of body parts, chassis components, etc. need to be stamped. Mechanical press production line can quickly repeat stamping actions and complete the production tasks of a large number of parts in a short time, greatly shortening the production cycle of automobiles and meeting the market's demand for rapid delivery of automobiles.

The continuous stamping working mode of this production line has greatly improved the overall production efficiency. Unlike single-machine stamping equipment that needs to stop for material loading and unloading after a single stamping, mechanical press production line achieves seamless connection of the stamping process through automated feeding and unloading devices. After the raw materials are fed into the first stamping station, they pass through multiple stamping stations in sequence, and different stamping processes such as punching, blanking, bending, etc. are continuously completed at each station until the final formed product is automatically unloaded. This continuous operation mode is like an efficient production line, which minimizes the idle time in the production process and increases the production efficiency exponentially. Taking the stamping of electronic equipment shells as an example, the production line can quickly stamp metal sheets into shells of various complex shapes, and can ensure a high production cycle to ensure that electronic equipment can be supplied to the market in a timely manner.

In addition, the mechanical press production line performs well in the stability of stamping speed. The high-precision servo motor or advanced hydraulic system it adopts can accurately control the movement speed and stroke of the slide of the press. During the long continuous stamping process, no matter what material, shape and size of the stamping parts are faced, the stamping speed can be maintained at a stable level, and there will be no product quality problems caused by speed fluctuations. This is especially important for some industries that have extremely high requirements for product precision and consistency, such as aerospace parts manufacturing. Stable stamping speed ensures that each component can be formed according to precise process parameters, laying a solid foundation for the high quality and high reliability of aerospace equipment.

In summary, the mechanical press production line has demonstrated unparalleled unique advantages in stamping speed with its high stamping frequency, continuous stamping working mode and stable speed control, which has effectively promoted the efficient and rapid development of the manufacturing industry.